Studio MBB

Machinery from Idea to production

Development, design, engineering and fabrication

Our

Services

-

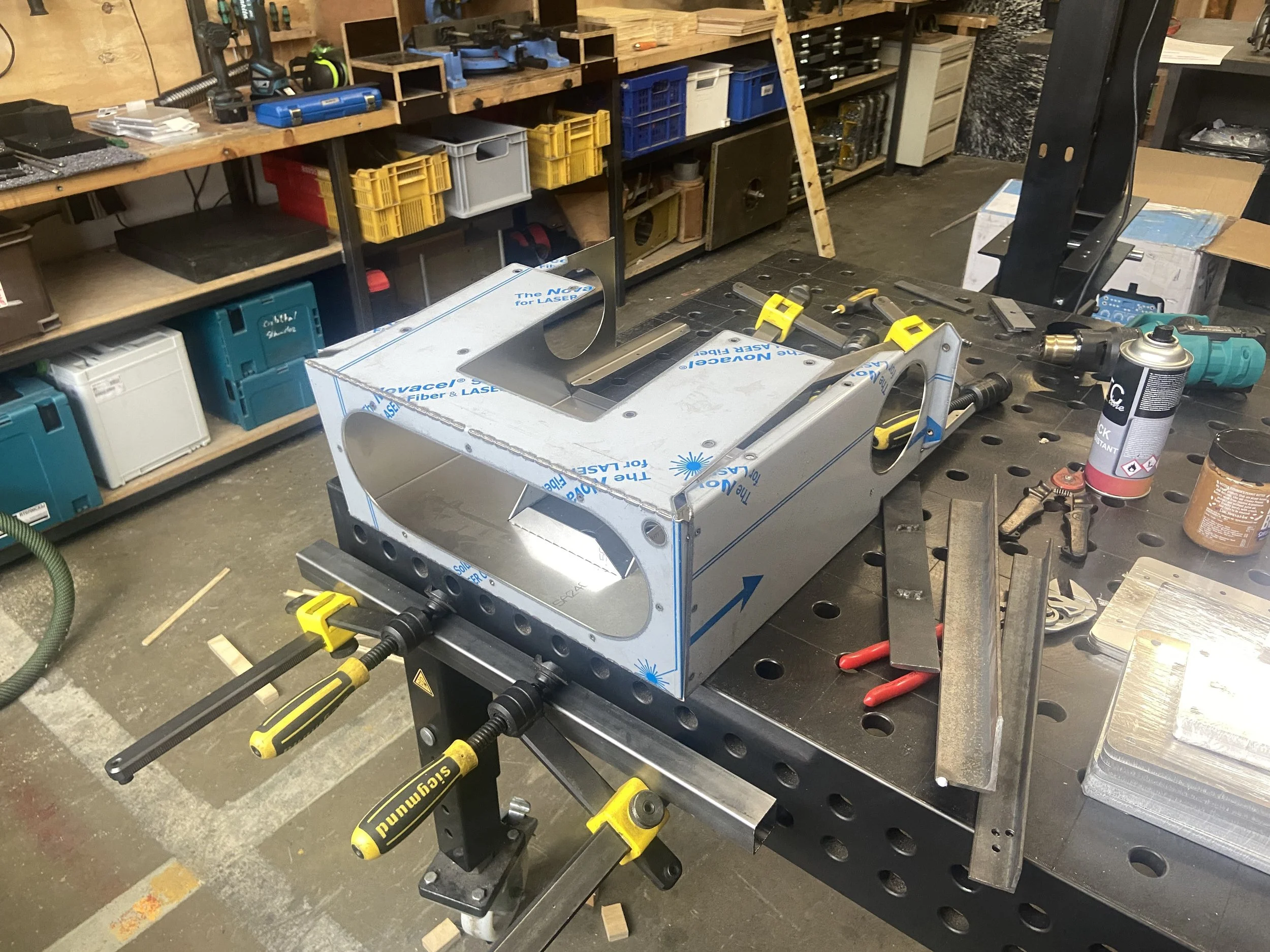

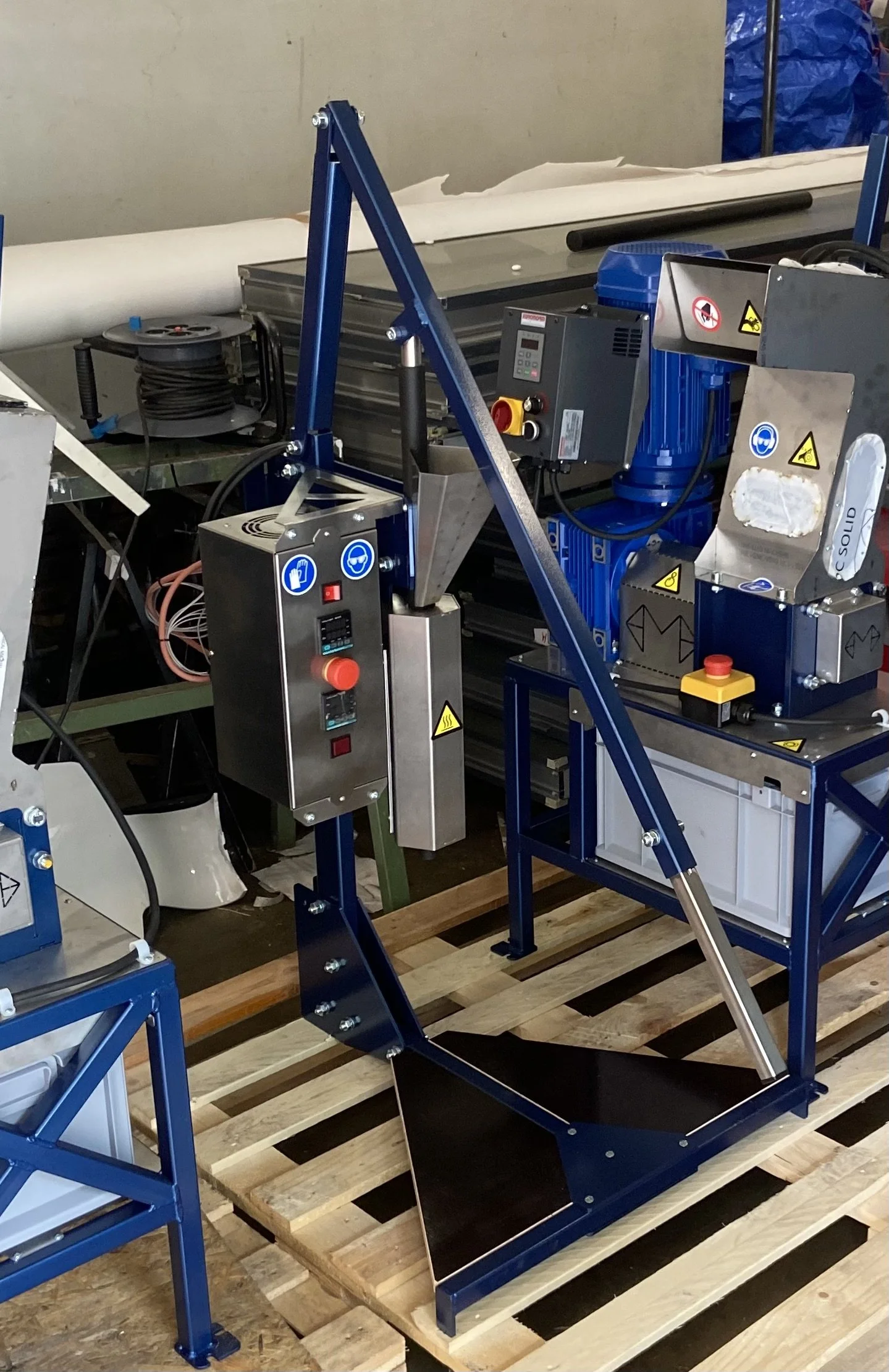

Machinery made to order

Studio MBB provides a variety of machinery for plastic recycling that can be manufactured to your order.

-

Custom Machinery

Next to the catalogue machinery, Studio MBB provides services to develop, design and manufacture machinery for your specific needs.

-

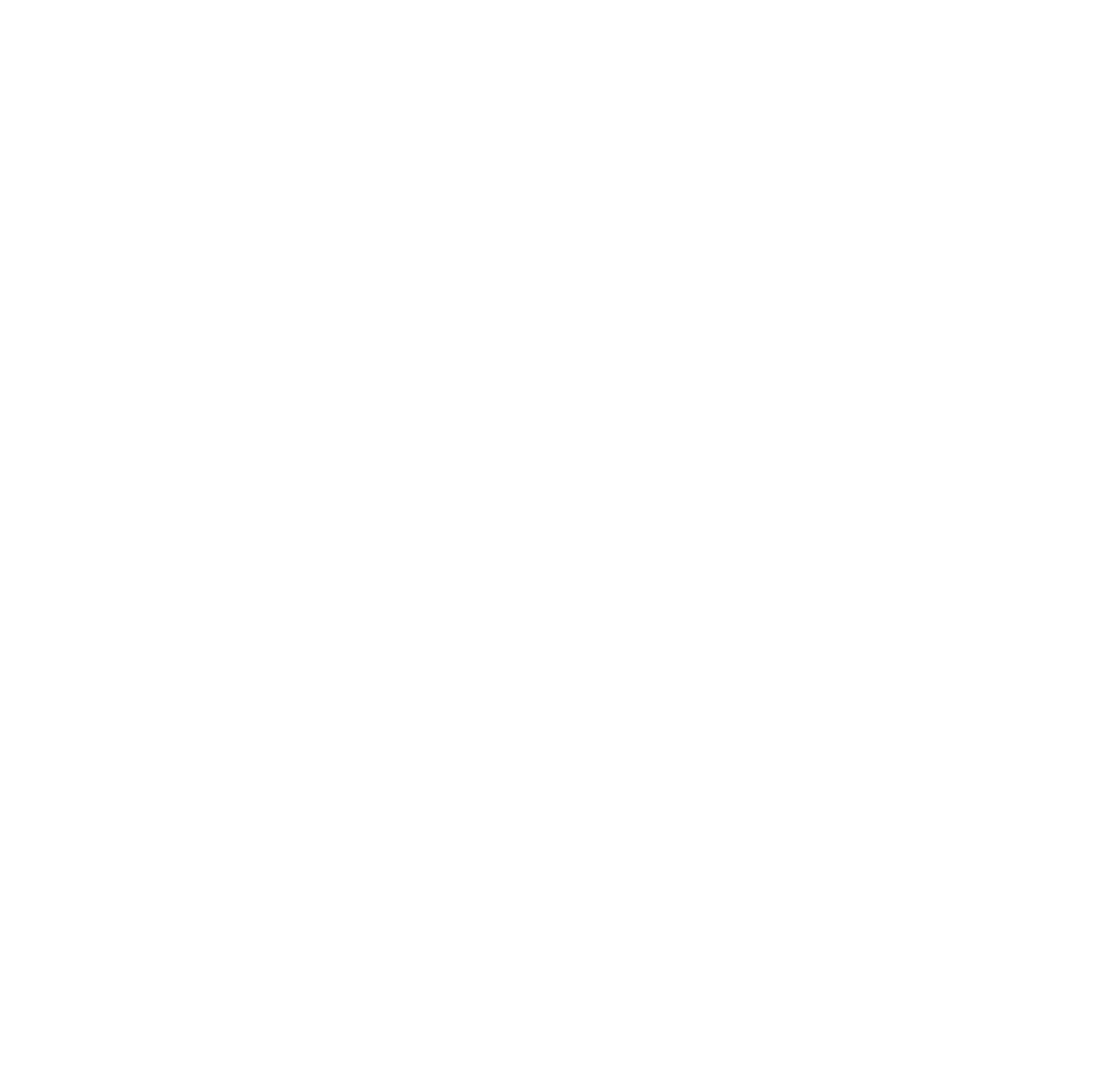

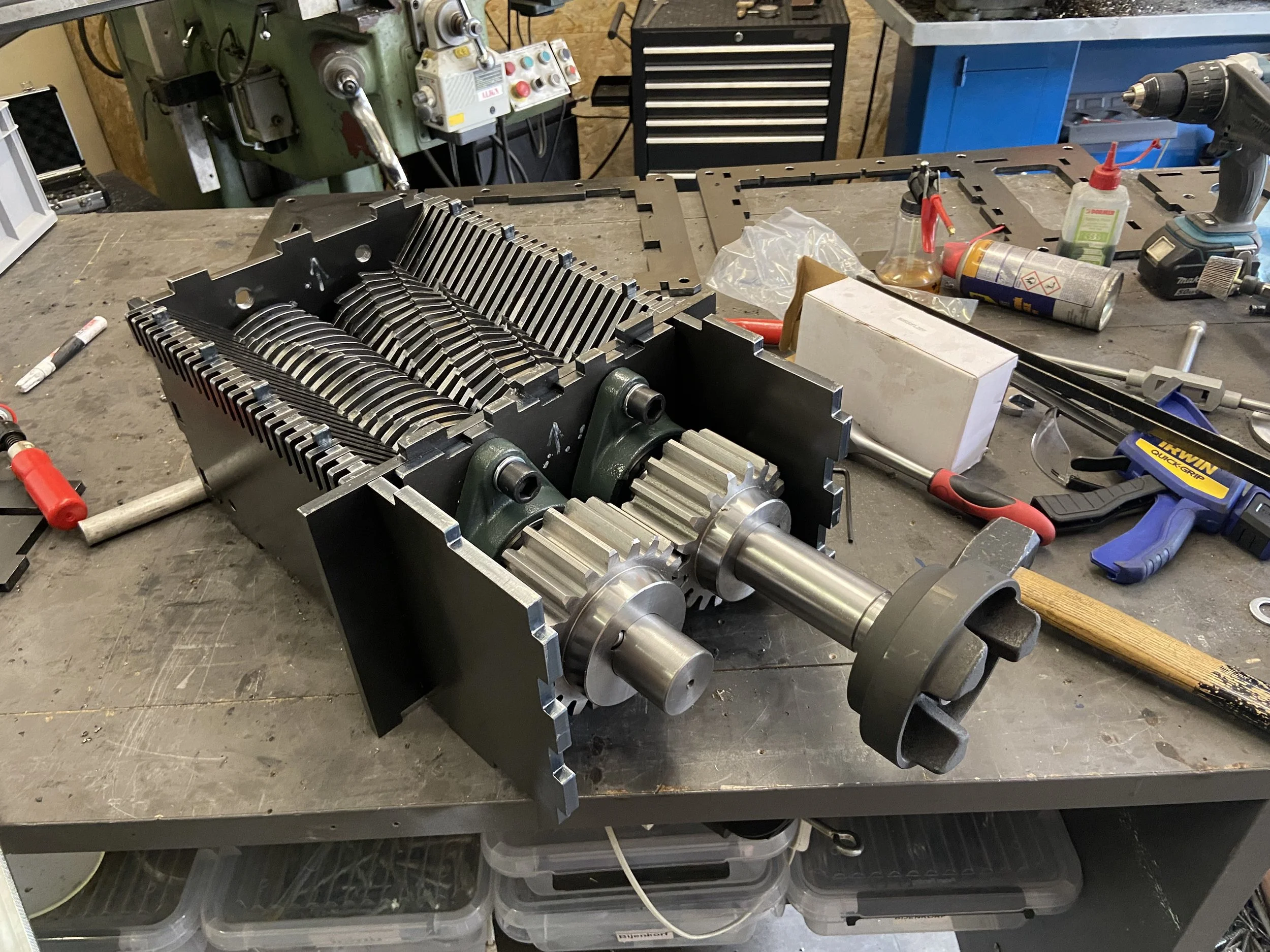

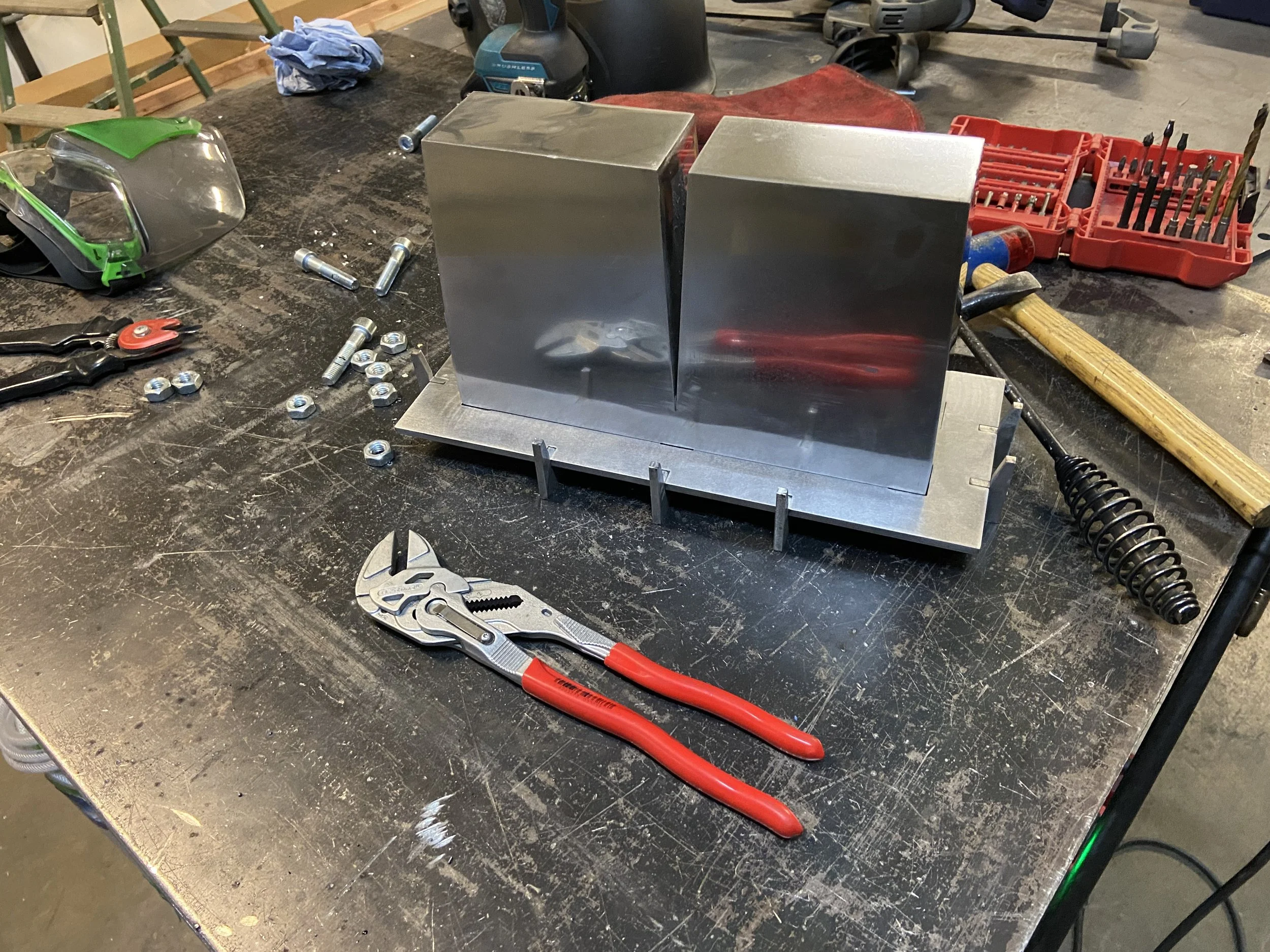

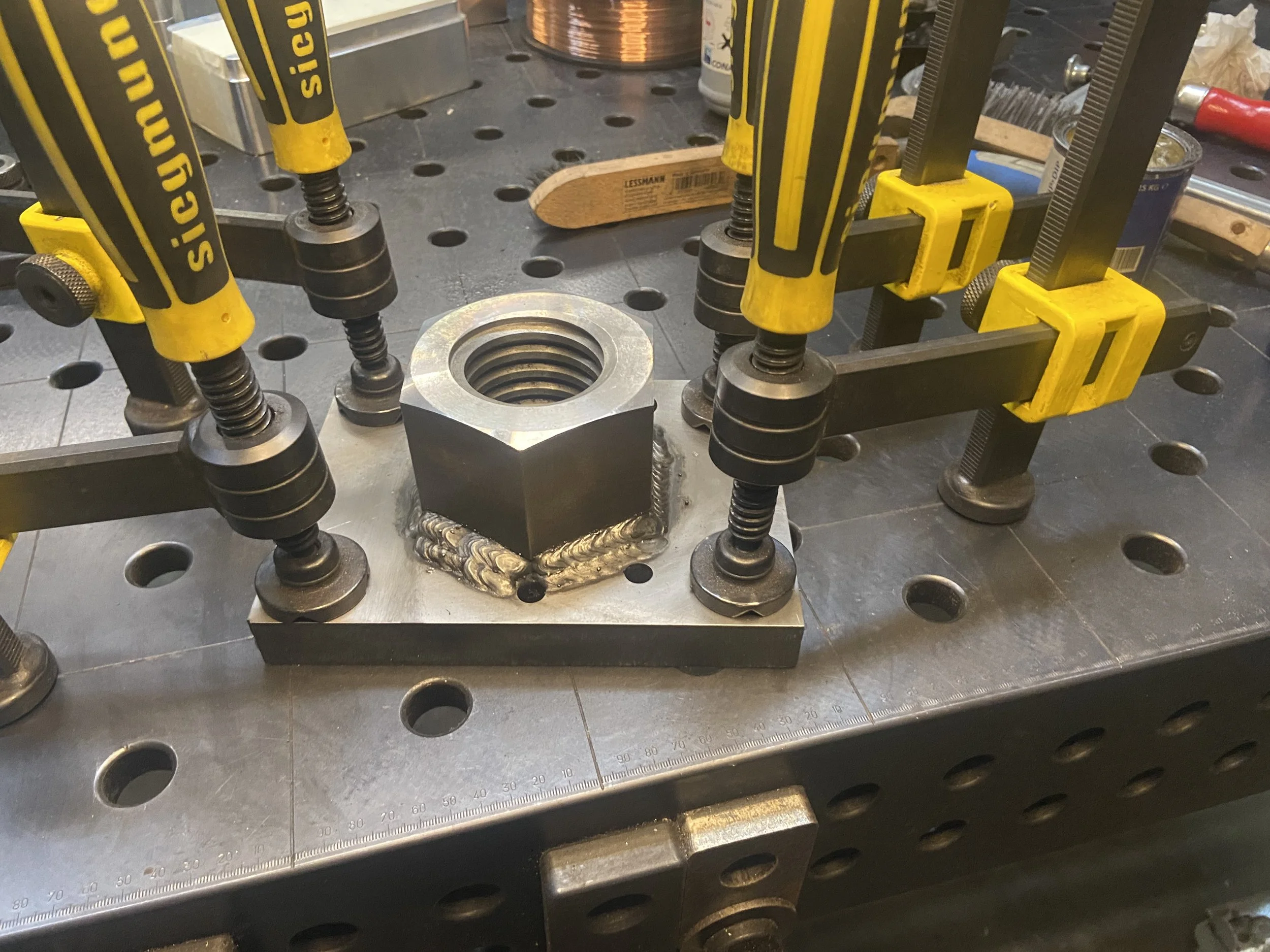

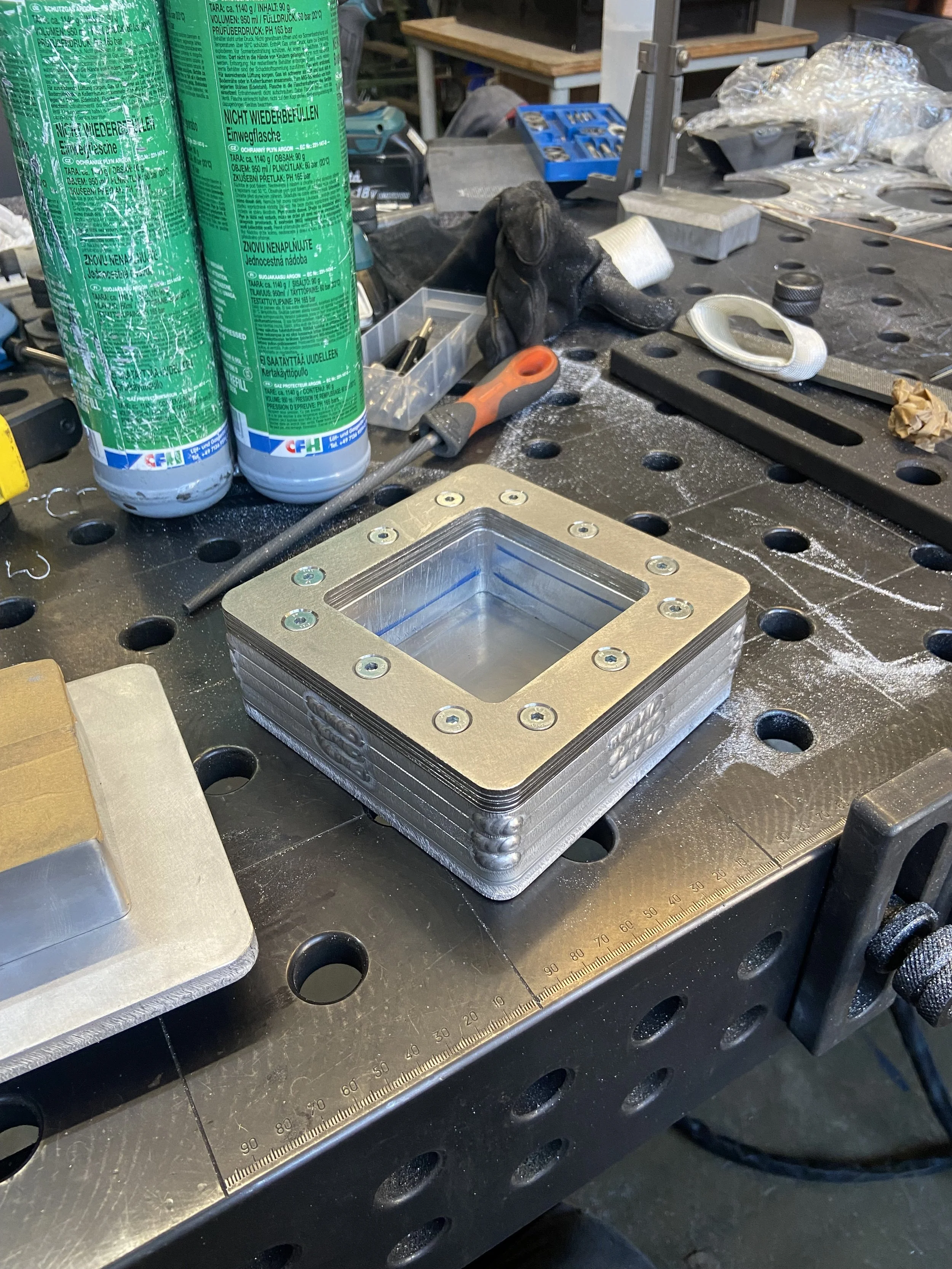

Prototyping, Machining and Welding

Complex or high precision parts, made from steel, stainless steel, aluminium or other engineering materials. Studio MBB can manufacture it for you!

-

Design and Engineering

Open-ended problem definitions are no problem for Studio MBB. We will find a solution for your problem and turn it into a design that can be manufactured

Our

Projects

About studio MBB

Studio MBB specializes in developing, designing, and manufacturing machinery for recycling. Our goal is to provide small scale organizations, such as educational institutions, NGOs, start-ups, and fab-labs, with high quality machinery that makes it easy for anyone to start recycling.

In addition to our standard machinery, we offer a customizing service to ensure that our machines meet the specific needs of each client. We also have the expertise to develop new machinery for processing a variety of materials, including bio-based materials.

At Studio MBB, we pride ourselves on our engineering and industrial design services, as well as our ability to fabricate, machine, and weld any complex parts, mechanisms, or structures.

At the heart of everything we do are our core values of simplicity, durability and safety. We are committed to finding cost-effective solutions that meet the needs of our clients.

Thank you for choosing Studio MBB – we look forward to working with you.

Recycling

Output

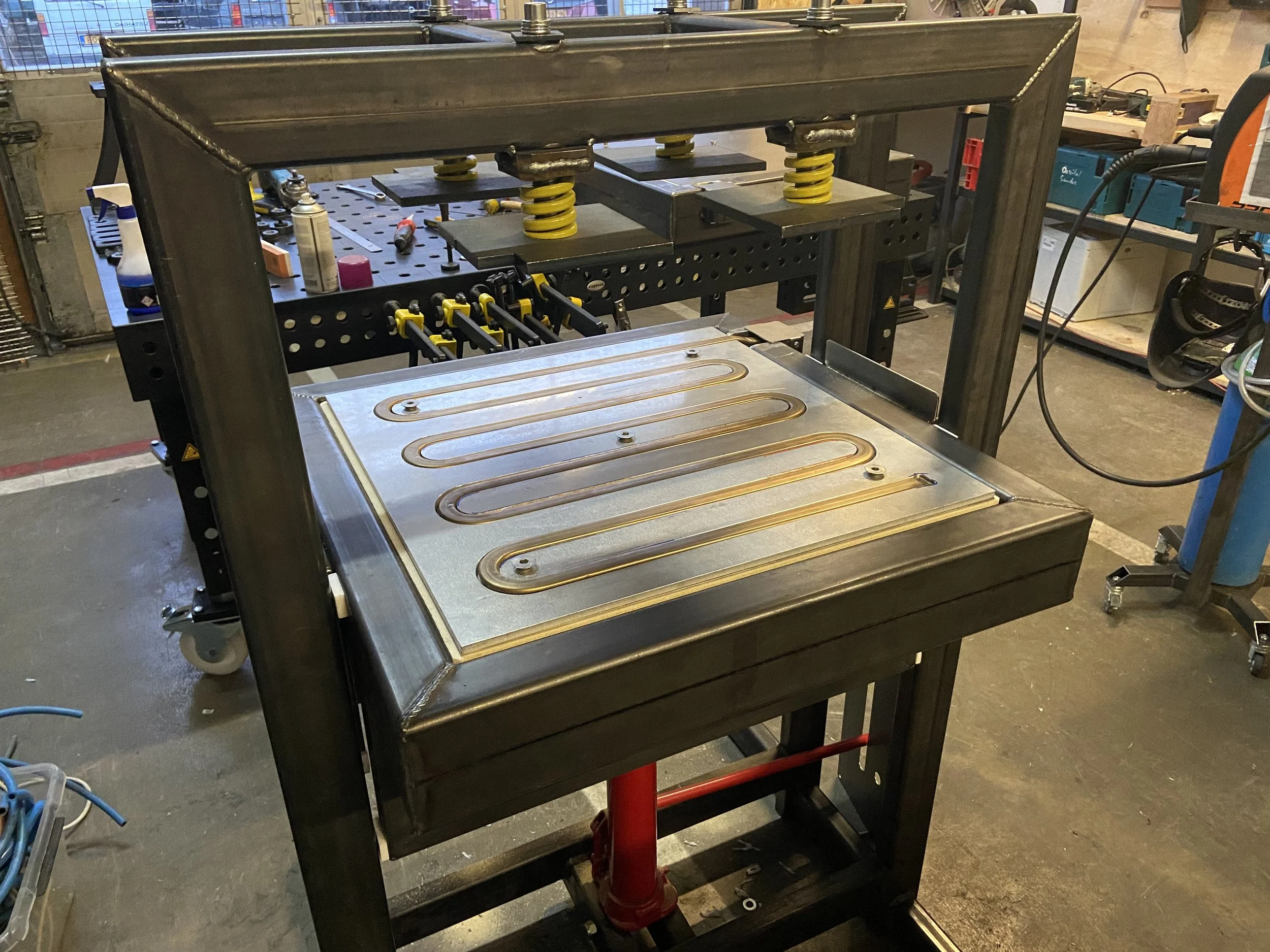

It all started with a graduation project

At Studio MBB, we have a strong passion for sustainability and innovation. It all began with our founder, Mark Bachrach, who was tasked with creating a solution to turn plastic waste into sheet material as part of his graduation project. With a goal of using only readily available tools and materials in low resource areas, Mark developed a sheet press made of standard steel profiles and sheet metal that could be assembled using just a drill, grinder, and electrode welder.

Mark's concept was an immediate success, as demonstrated in this video. Building on this success, he worked with Precious Plastic to improve the sheet press for their platform. This collaboration eventually led to the creation of Studio MBB, which is dedicated to providing machinery solutions for recyclers around the world. Our goal is to help create a more sustainable future by empowering individuals and organizations to recycle waste and turn it into valuable materials.